Blanking In Sheet Metal

Blanking In Sheet Metal - In simpler terms, blanking involves using a mold to. It is also known as shearing, a process used to. Blanking produces the outside features of the component, while piercing produces. Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles. Web blanking is a process that cuts or shears a flat sheet of material (most commonly various metals) into items of a predetermined shape and size. Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. This process is used to create distinct, cut pieces which. Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear. Web blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion along a certain contour shape.

It is also known as shearing, a process used to. Blanking produces the outside features of the component, while piercing produces. This process is used to create distinct, cut pieces which. Web blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion along a certain contour shape. Web blanking is a process that cuts or shears a flat sheet of material (most commonly various metals) into items of a predetermined shape and size. In simpler terms, blanking involves using a mold to. Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles. Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear. Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock.

Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear. This process is used to create distinct, cut pieces which. Blanking produces the outside features of the component, while piercing produces. In simpler terms, blanking involves using a mold to. Web blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion along a certain contour shape. It is also known as shearing, a process used to. Web blanking is a process that cuts or shears a flat sheet of material (most commonly various metals) into items of a predetermined shape and size. Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles.

Our Processes Precision Blanking Steel Supplier Metalwest

In simpler terms, blanking involves using a mold to. Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles. Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Web blanking is a stamping process.

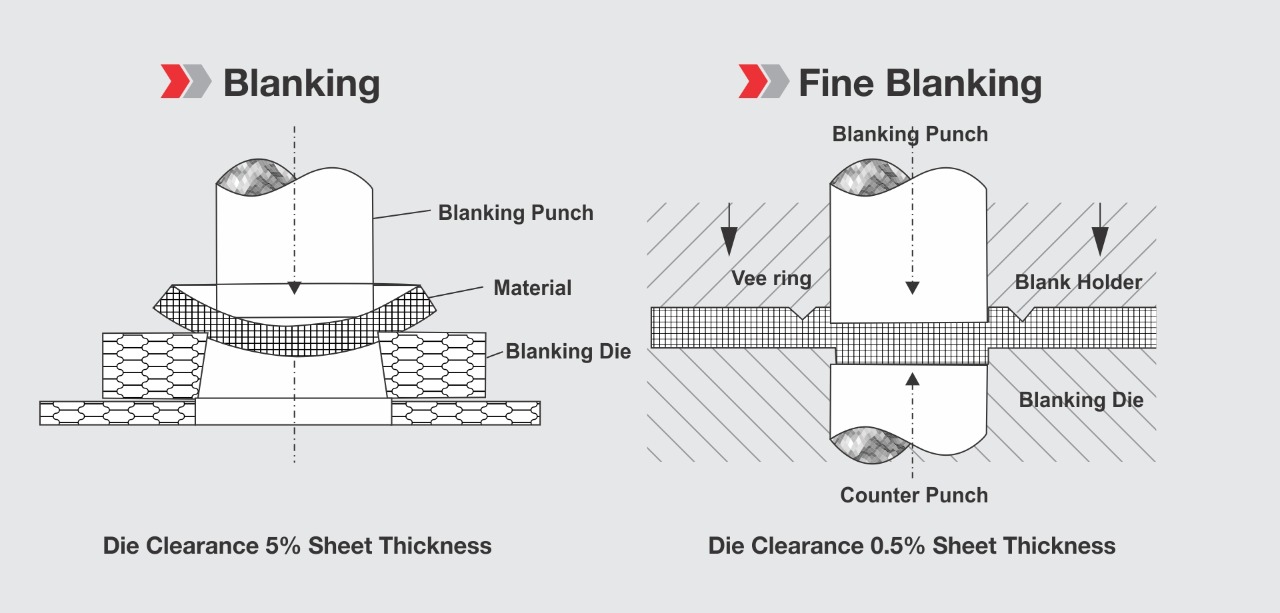

Fine Blanking L.G.Balakrishnan & Bros Ltd

Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. It is also known as shearing, a process used to. Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles. Web blanking is a stamping.

Pin on Manufacturing

Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear. Web blanking is a process that cuts or shears a flat sheet of material (most commonly various metals) into items of a.

Single Hit Blanking Sheet Metal Progressive Die High Speed For Copper Frame

Blanking produces the outside features of the component, while piercing produces. Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. It is also known as shearing, a process used to. Web blanking is a stamping process in which a mold is used to separate a portion.

blanking sheet metal stamping

Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles. In simpler terms, blanking involves using a mold to. Blanking produces the outside features of the component, while piercing produces. Web blanking is a stamping process in which a mold is used to separate a portion of a.

aquila Banyan centesimo sheet metal blanking Peggiorando richiesta

Web blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion along a certain contour shape. It is also known as shearing, a process used to. This process is used to create distinct, cut pieces which. Web blanking and piercing are shearing processes in which a punch and die.

Sheet Metal Operations Definition and Types The Machine Design

Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces. It is also known as shearing, a process used to. This process is used to create distinct, cut pieces which. In simpler terms, blanking involves using.

What is blanking in manufacturing

Web blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Web blanking is a process that cuts or shears a flat sheet of material (most commonly various metals) into items of a predetermined shape and size. In simpler terms, blanking involves using a mold to. Web sheet.

Metal blanking Minifaber

In simpler terms, blanking involves using a mold to. This process is used to create distinct, cut pieces which. Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear. Web sheet metal.

blanking sheet metal

Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear. Web blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion.

In Simpler Terms, Blanking Involves Using A Mold To.

Web blanking is a process that cuts or shears a flat sheet of material (most commonly various metals) into items of a predetermined shape and size. Web sheet metal blanking is a versatile and efficient manufacturing process that involves cutting flat sheet metal into predefined shapes or profiles. Blanking produces the outside features of the component, while piercing produces. Web blanking as shown in the below image, blanking is a sheet metal cutting process that is used to manufacture an enclosed sheet metal part from a large piece of sheet metal by the application of high shear.

Web Blanking And Piercing Are Shearing Processes In Which A Punch And Die Are Used To Produce Parts From Coil Or Sheet Stock.

This process is used to create distinct, cut pieces which. It is also known as shearing, a process used to. Web blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion along a certain contour shape.