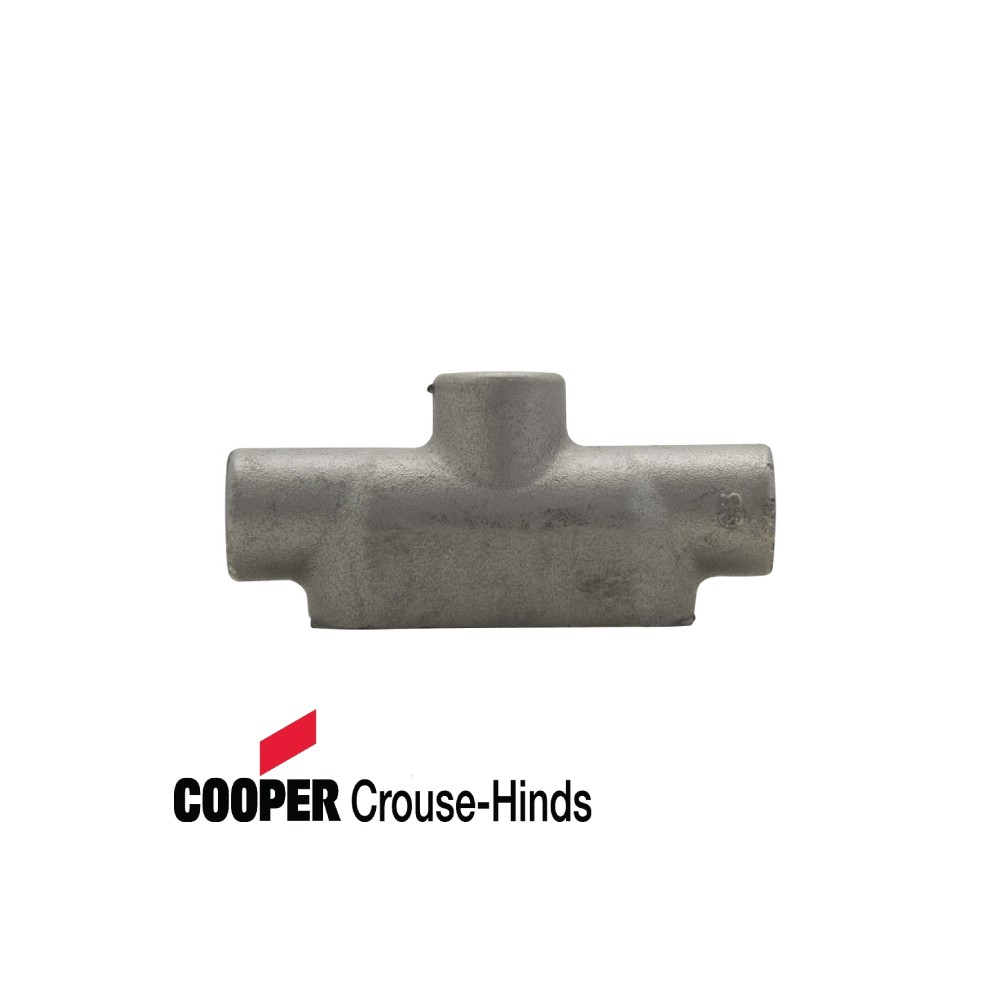

Form 7 Condulet

Form 7 Condulet - Nec/cec — suitable for use in the following hazardous locations: For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Many shapes and sizes are available for rigid threaded conduit. Equivalent fm7tm and form 7tm units have identical applications and installation dimensions. Form 7 condulet® outlet bodies approach conduit in size for neat, compact installations form 8 and mark 9 bodies provide more room for heavier conductors many shapes and sizes are available for rigid threaded conduit conduit hubs have tapered threads and feature integral bushings for protection of wire insulation Form 35, form 7, form 8 and form 9. Many shapes and sizes are available for rigid threaded conduit. Web form 7™ iron conduit bodies, covers and gaskets for use with rigid steel, rigid aluminum and imc conduit. Web form 7 condulet outlet bodies approach conduit in size for neat, compact installations. Flat back design provides greater cubic content for easier wire pulling, and more room for splicing.

For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an integrally gasketed cover saves customers inventory and labor costs. These conduit bodies serve as pulling fittings and permit access to conductors for splicing and maintenance. Condulet form 7 conduit outlet bodies and covers. Tapered threads hubs (npt) flat back designs for greater wiring capacity and surface mounting. Class i, division 2 per nec 501.10(b)(4) wet locations, nema 3r with cover and gasket conduit bodies trade size (inches) c lb ll max. Web the most common condulet types in the market are: Equivalent fm7tm and form 7tm units have identical applications and installation dimensions. Form 7 condulet® outlet bodies approach conduit in size for neat, compact installations form 8 and mark 9 bodies provide more room for heavier conductors many shapes and sizes are available for rigid threaded conduit conduit hubs have tapered threads and feature integral bushings for protection of wire insulation Form 35, form 7, form 8 and form 9.

Many shapes and sizes are available for rigid threaded conduit. These conduit bodies serve as pulling fittings and permit access to conductors for splicing and maintenance. Form 35, form 7, form 8 and form 9. Each has their specific dimensions, sizes, wire capacity and covers. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an integrally gasketed cover saves customers inventory and labor costs. Nec/cec — suitable for use in the following hazardous locations: Equivalent fm7tm and form 7tm units have identical applications and installation dimensions. Condulet form 7 conduit outlet bodies and covers. Web electrical and industrial | power management solutions | eaton Web the most common condulet types in the market are:

CROUSEHINDS SERIES CONDULET FORM 7 CONDUIT OUTLET BODY Modern

Web form 7™ iron conduit bodies, covers and gaskets for use with rigid steel, rigid aluminum and imc conduit. Flat back design provides greater cubic content for easier wire pulling, and more room for splicing. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an integrally gasketed cover saves customers.

C77SA CROUSE HINDS COPPER FREE ALUMINUM STYLE C/FORM 7 CONDULET CONDUIT

Web form 7 condulet outlet bodies approach conduit in size for neat, compact installations. For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Web electrical and industrial | power management solutions | eaton Web form 7™ iron conduit bodies, covers and gaskets for use.

CROUSEHINDS SERIES CONDULET FORM 7 CONDUIT OUTLET BODY Modern

Internal volume and maximum wire clearly marked on castings. Many shapes and sizes are available for rigid threaded conduit. Class i, division 2 per nec 501.10(b)(4) wet locations, nema 3r with cover and gasket conduit bodies trade size (inches) c lb ll max. Web form 7 condulet outlet bodies approach conduit in size for neat, compact installations. Complete interchangeability with.

LOT OF 2 EATON CROUSE HINDS LL67 FORM 7 CONDULET eBay

In addition to making bends in a conduit system, they allow connections for branch runs. For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an.

Condulet Form 7 Conduit Outlet Bodies and Covers Royaltec

For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an integrally gasketed cover saves customers inventory and labor costs. Nec/cec — suitable for use in.

EATON CROUSE HINDS LB47 FORM 7 CONDULET 11/4OUTLET BODY eBay

Web form 7 condulet outlet bodies approach conduit in size for neat, compact installations. These conduit bodies serve as pulling fittings and permit access to conductors for splicing and maintenance. For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Many shapes and sizes are.

CROUSEHINDS SERIES CONDULET FORM 7 CONDUIT OUTLET BODY Modern

In addition to making bends in a conduit system, they allow connections for branch runs. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an integrally gasketed cover saves customers inventory and labor costs. Complete interchangeability with other manufacturers form 7 conduit bodies. Equivalent fm7tm and form 7tm units have.

CrouseHinds X37 1" Form 7 Condulet Conduit Body

Many shapes and sizes are available for rigid threaded conduit. Condulet form 7 conduit outlet bodies and covers. In addition to making bends in a conduit system, they allow connections for branch runs. Web form 7 condulet outlet bodies approach conduit in size for neat, compact installations. Form 35, form 7, form 8 and form 9.

CROUSEHINDS SERIES CONDULET FORM 7 WEDGE NUT COVER Modern Electrical

These conduit bodies serve as pulling fittings and permit access to conductors for splicing and maintenance. For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body. Condulet form 7 conduit outlet bodies and covers. Form 7 condulet® outlet bodies approach conduit in size for neat,.

EATON CROUSE HINDS LB47 FORM 7 CONDULET 11/4OUTLET BODY eBay

Form 35, form 7, form 8 and form 9. Form 7 condulet® outlet bodies approach conduit in size for neat, compact installations form 8 and mark 9 bodies provide more room for heavier conductors many shapes and sizes are available for rigid threaded conduit conduit hubs have tapered threads and feature integral bushings for protection of wire insulation Complete interchangeability.

Tapered Threads Hubs (Npt) Flat Back Designs For Greater Wiring Capacity And Surface Mounting.

Web form 7™ iron conduit bodies, covers and gaskets for use with rigid steel, rigid aluminum and imc conduit. Condulet form 7 conduit outlet bodies and covers. Our form 7 family features an exclusive snaptight and wedge nut cover attachment for an unobstructed cover opening, and an integrally gasketed cover saves customers inventory and labor costs. For instance, the main difference between form 7, form 8 or form 9 types is the way the cover is attached to the conduit body.

Flat Back Design Provides Greater Cubic Content For Easier Wire Pulling, And More Room For Splicing.

Class i, division 2 per nec 501.10(b)(4) wet locations, nema 3r with cover and gasket conduit bodies trade size (inches) c lb ll max. Nec/cec — suitable for use in the following hazardous locations: Web electrical and industrial | power management solutions | eaton These conduit bodies serve as pulling fittings and permit access to conductors for splicing and maintenance.

Web Form 7 Condulet Outlet Bodies Approach Conduit In Size For Neat, Compact Installations.

Web the most common condulet types in the market are: Many shapes and sizes are available for rigid threaded conduit. Internal volume and maximum wire clearly marked on castings. Many shapes and sizes are available for rigid threaded conduit.

Form 7 Condulet® Outlet Bodies Approach Conduit In Size For Neat, Compact Installations Form 8 And Mark 9 Bodies Provide More Room For Heavier Conductors Many Shapes And Sizes Are Available For Rigid Threaded Conduit Conduit Hubs Have Tapered Threads And Feature Integral Bushings For Protection Of Wire Insulation

Form 35, form 7, form 8 and form 9. Equivalent fm7tm and form 7tm units have identical applications and installation dimensions. Complete interchangeability with other manufacturers form 7 conduit bodies. Web form 7 condulet outlet bodies approach conduit in size for neat, compact installations.